OMRON

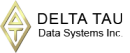

- PMAC HISTORY

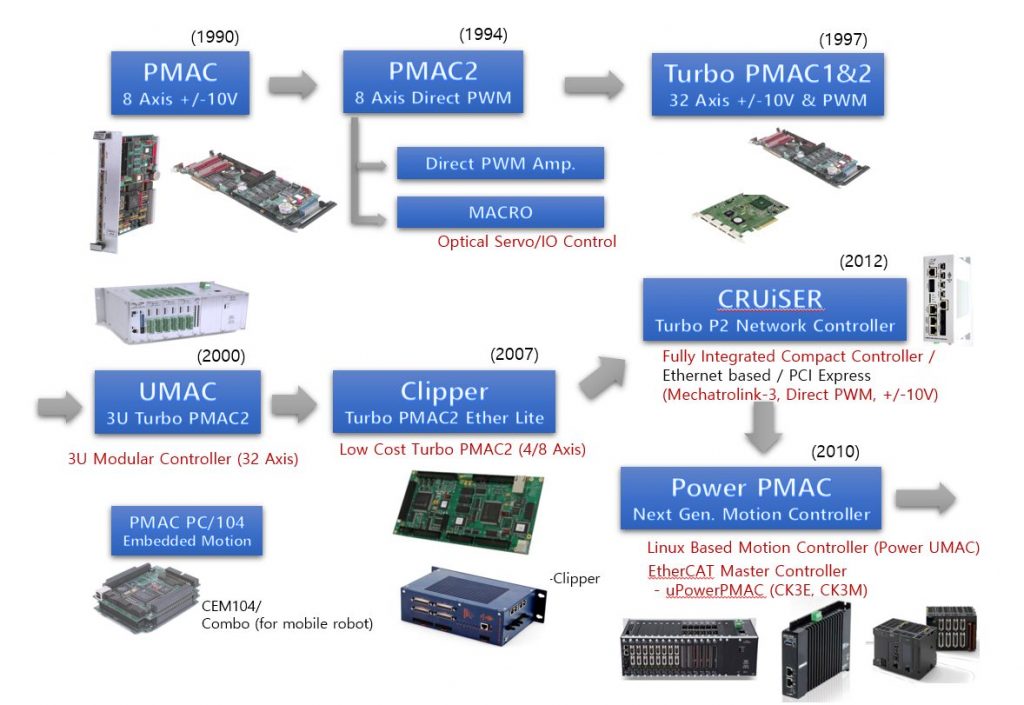

- What is PMAC? (Programmable Multi Axis Controller)

What is UMAC? (Universal Machine & Automation Controller)

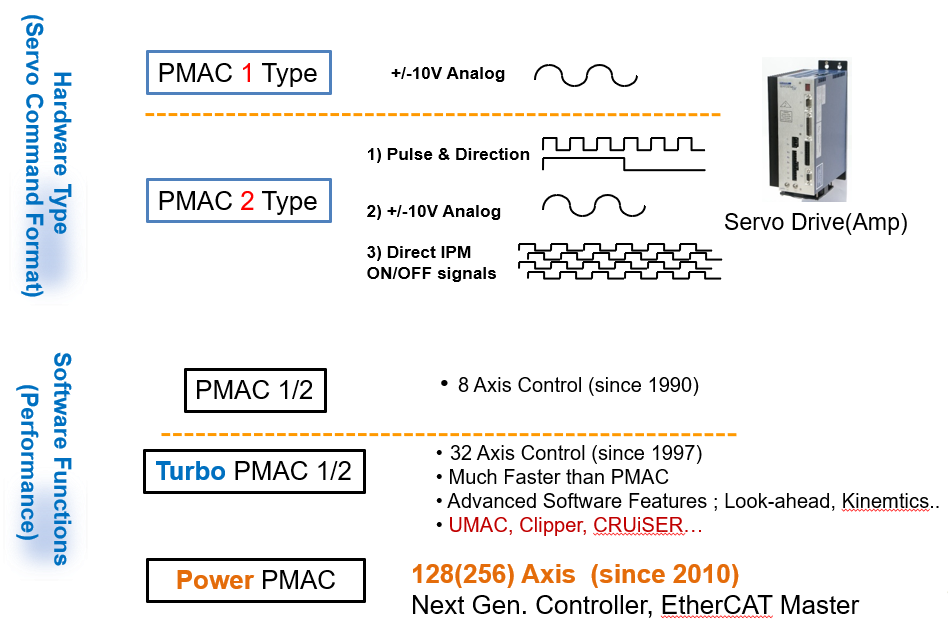

• 일반 PMAC (Non Turbo PMAC) 8축 동시 제어, Tutbo PMAC 32축 제어

• 동시 프로그램 실행 : 32 PLC, 32 PLCC Programs // 16 [8 Non-Turbo] motion programs

• UMAC : 3U “Modular” Format Turbo PMAC2 Controller

• Standalone 또는 PC-Based Command Application

• Trajectory Profile Generate (모션 궤적 생성) : 모션 Move 프로파일 생성을 위한 모든 계산 수행

• Feedback Processing : 엔코더 등 다양한 종류의 피드백 신호 처리

• Digital Servo Filter : 내장된 고성능 PID filter 에 의한 Servo update

• Commutation (Optional) : 모터 상간의 전류 지령을 위한 Commutation

• Execute Motion, PLC (Sequential) Program

• Communication with Host PC

• House Keeping (Self-managing and saftey check)

- PMAC 분류

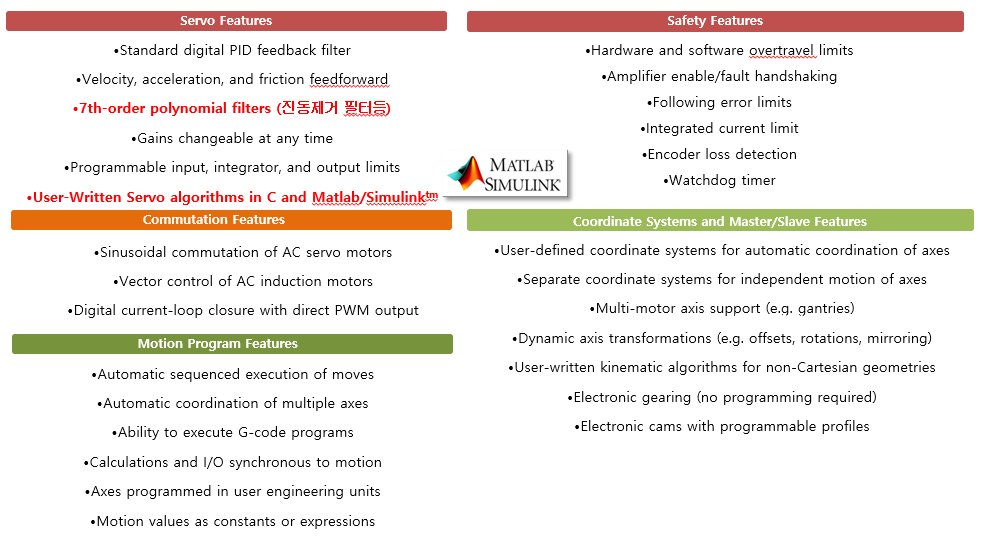

- Important PMAC Features

• Data Gathering, 48Mem. Location, 24Bits

• PLC’s & PLCC’s, PMAC Script language

• Rapid / Linear / Circle / Spline / PVT & JOG / HOME

• 좌표계 회선 & 변환 – Coordinate Rotation (2D & 3D) & Translation

• 위치 보정 기능 – Multiple/Automatic Axis Lead Screw & Backlash Compensation

• Hardware 24-Bits Position “Capture” & Position “Compare”

• Built-In 1/T quadration interpolator

• Go, Until Trigger / Alter Destination on Trigger

• “Open Servo / User Written High Level (Basic-like) Code written & Complied for execution by PMAC.

• All PMAC’s (type or speed) share a Common Programming LAnguage Only Set-up is different

- Turbo PMAC Features

• FAST CPU 56301, 2, 3, 9, 11(Flex) – 40 – 240Mhz (x1.5 eq.), Large Memory

• Flash-Ram and Real-time Clock, with ID chip

• 32 Axis control in 16 Coordinates

• PID (8) and Advanced Pole Placement Servo Algorithm (32 parameters)

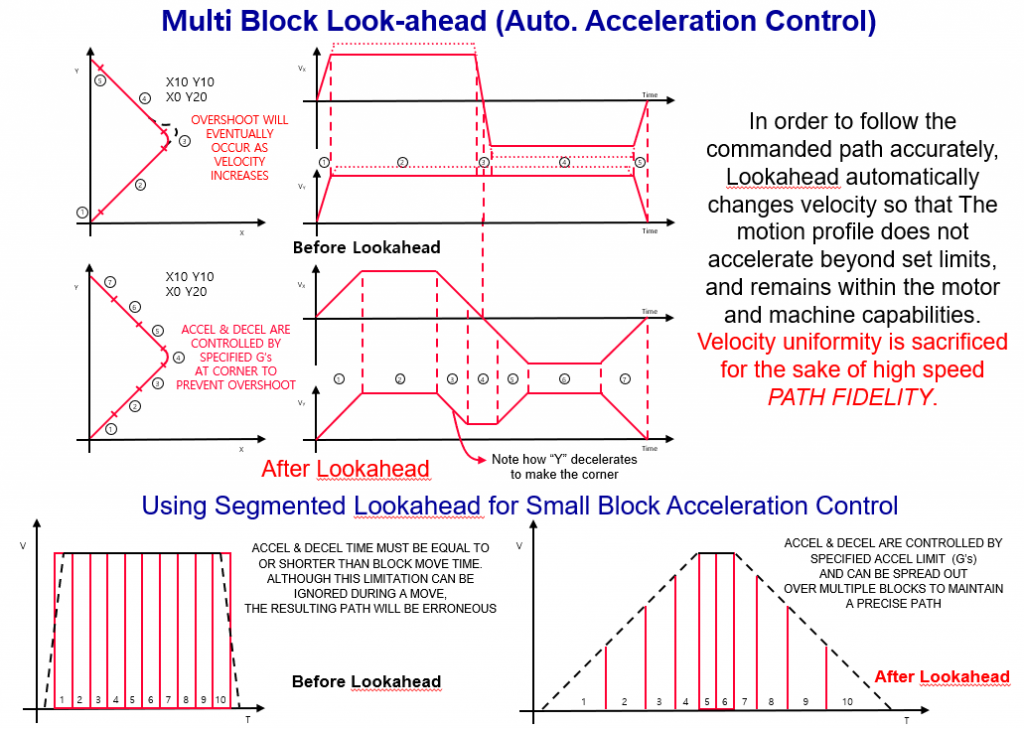

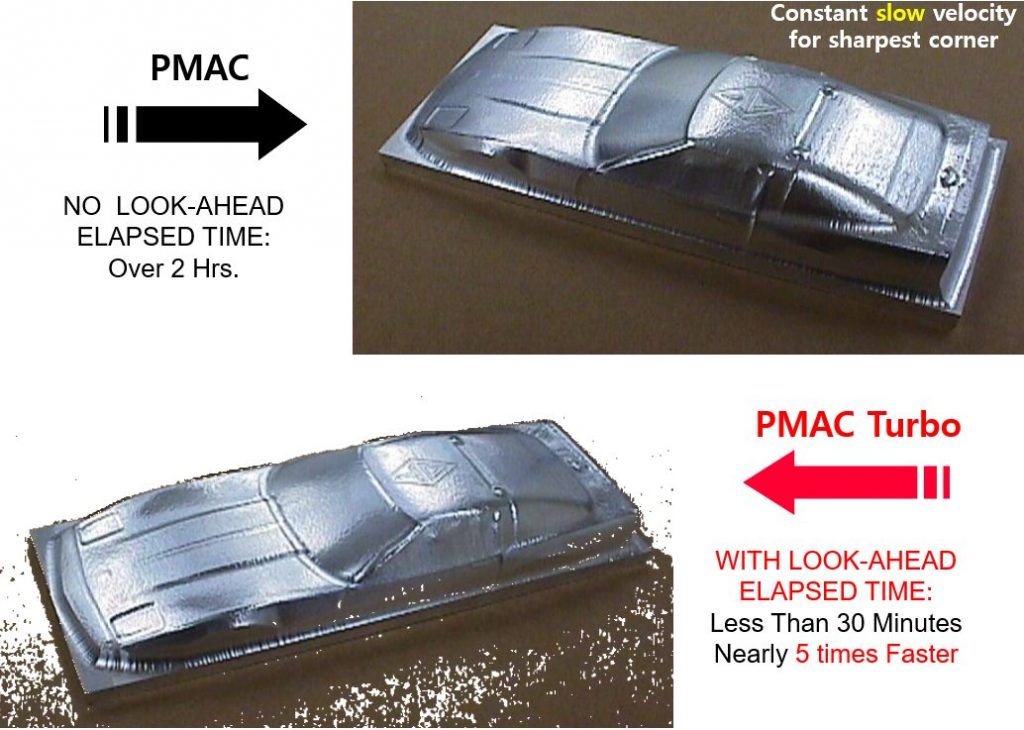

• Multi-Block High Speed, Segmented Lookahead with Synchronous I/O Capability

• Acceleration & Jerk Control

• Reverse & Retrace capability

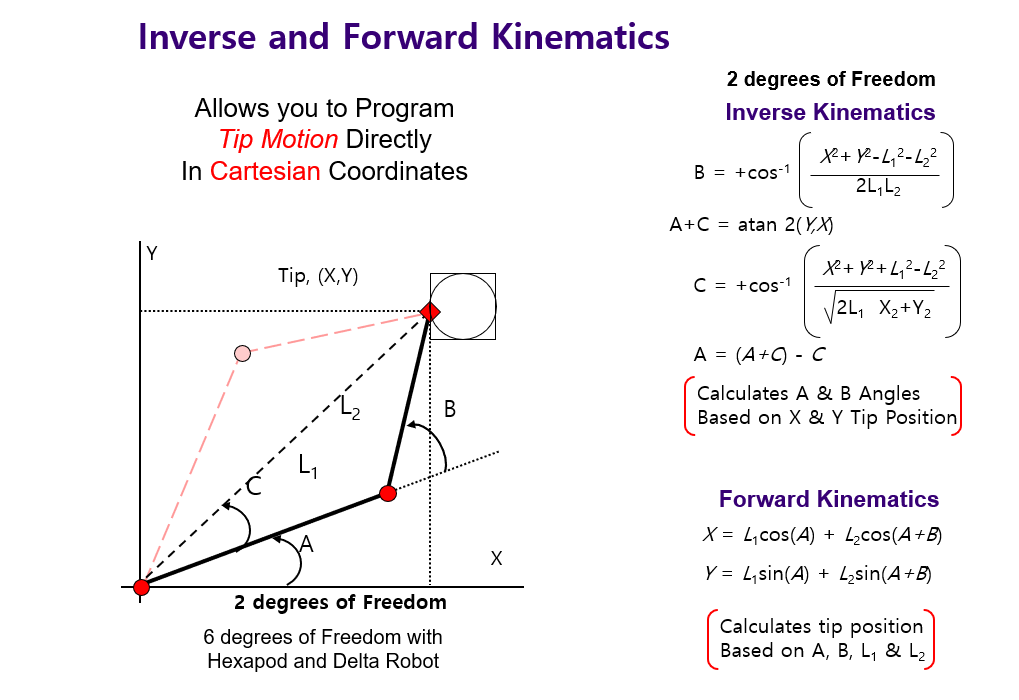

• Inverse Kinematics & 5th Axis NC Applications

• Cascaded Servo loops (Velocity/Force Loop)

• Auto ID – Identify and Verify Peripheral Connection on Power Turn-on

• Multiport Communication with Scheduler

a) USB2 & Ethernet b) 2x RS232 ports c) Parallel Host Port

d) Internal & External Dual Port RAM e) PLC f) MACRO (optic fiber)

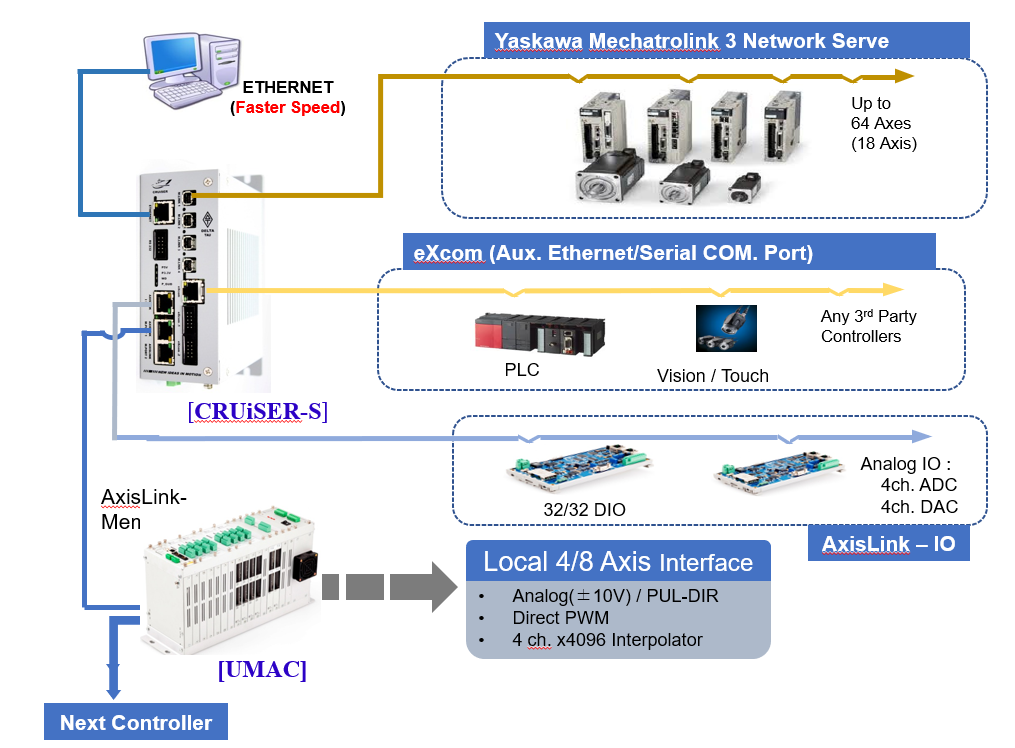

- UMAC / CRUiSER System LAYOUT

- UMAC (3U Turbo PMAC2 Flexible Controller)

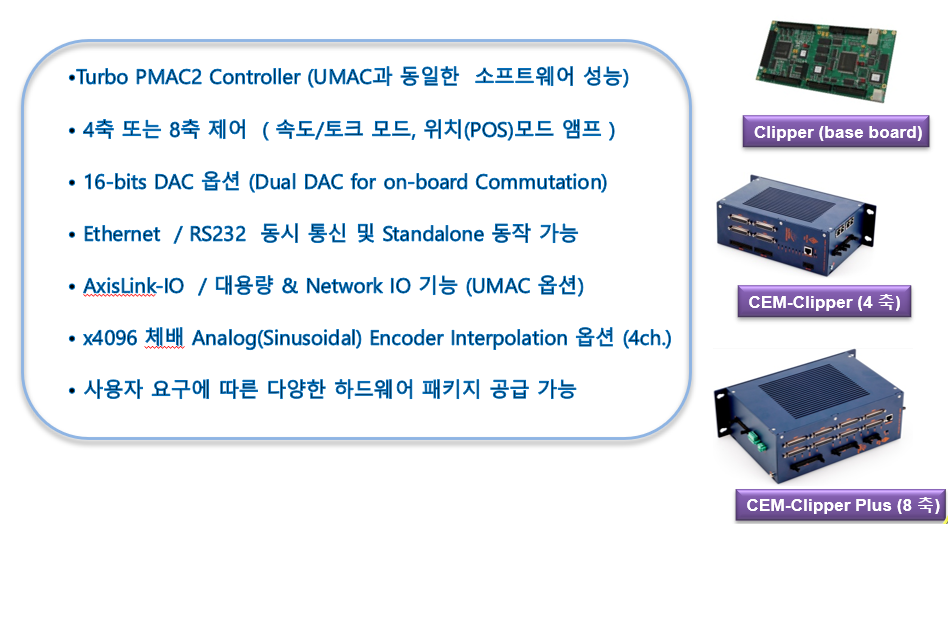

- CEM-Clipper 경제형 Turbo PMAC2 Ethernet Contoller

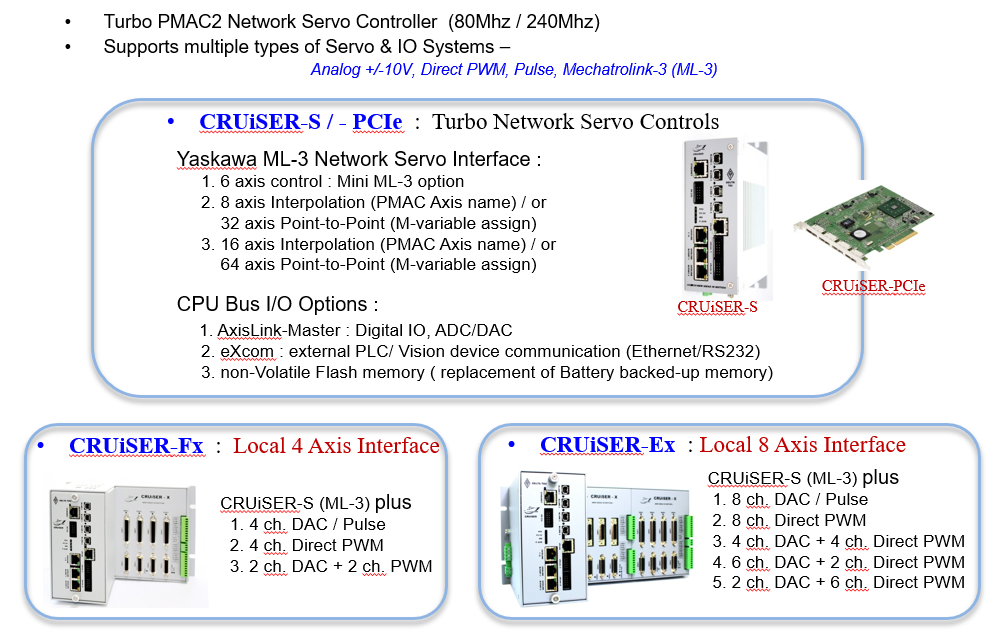

- CRUiSER - Fully Integrated Netword Servo Motion Controller

(Turbo PMAC2 Controller)

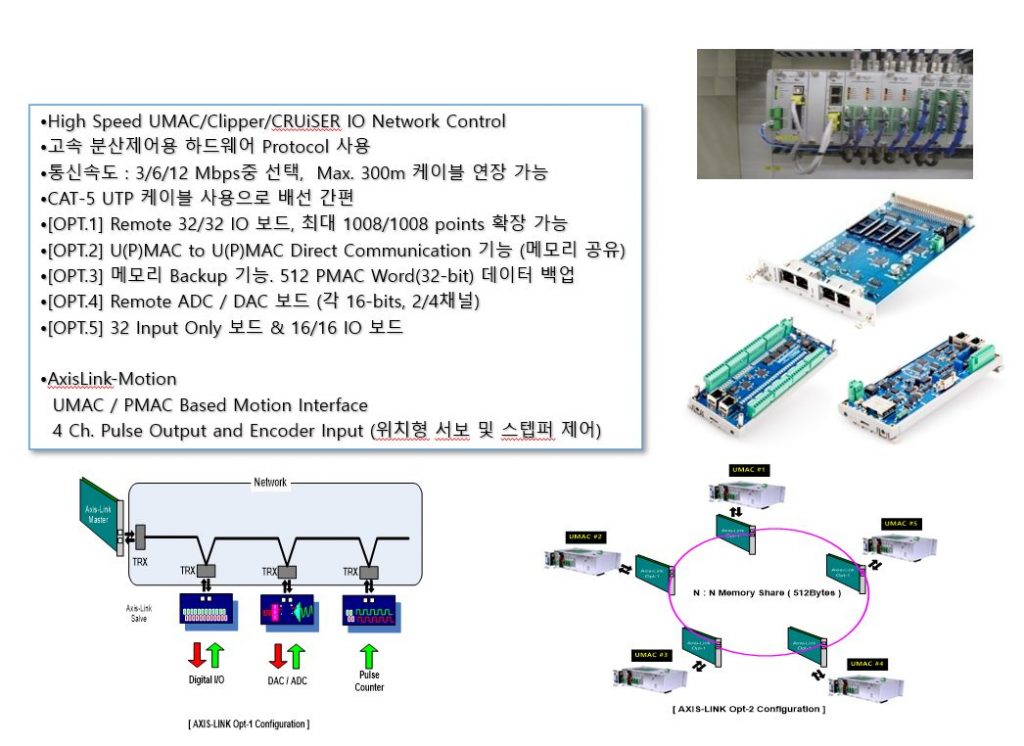

- Axislink System (Multi-Purposes Industrial Network Interface)

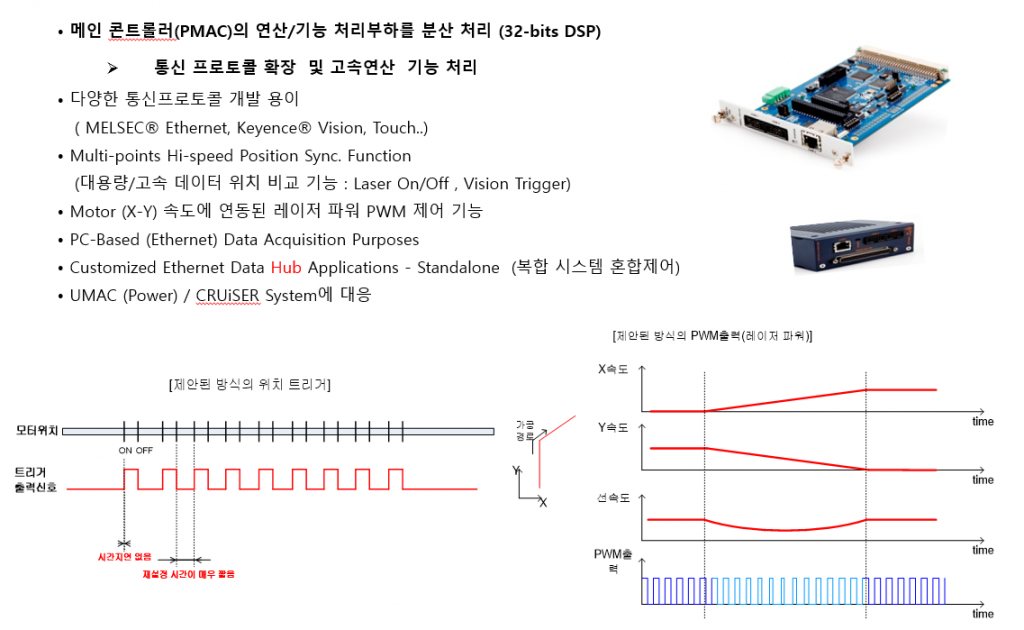

- eXcom 16/32 (General Purpose Supplemental DSP Board)

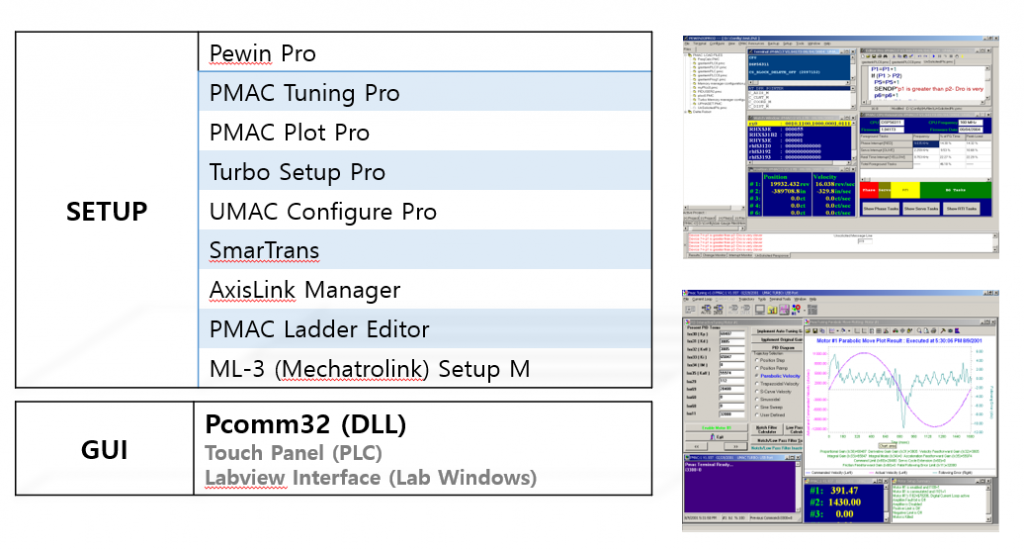

- Software 구성

- Power PMAC (High Performance RTOS-linux Motion Controller)

• 1.0~1.2Ghz Dualcore Linux OS Built-in Motion controller

• Max. 256 서보 모터 제어 가능 (MACRO, Network System 필요)

• Full 32-64Bit Architecture / Hardware 64-bit Floating points (고속연산 및 대용량 Dynamic Range)

• 대용량 내부 메모리 (최대 2GB DDRAM, 1G 이상 NAND Flash for User Programs)

• Support PC Perpheral Memory devices (USB/SD)

• Built-in Ethernet 1Gbps, USB 2.0

• 2 port PCI Express 확장버스 옵션 (Video 및 Vision 보드 장착)

• 다양한 Power PMAC 모델 출시 (Power UMAC / CK3E, CK3M)

- Power PMAC (DSP Gate3)

• Next Gen. Function/Logic 설계(기존 DSP Gate2 대비 약 3배의 동작 속도 향상)

• Servo / IO / MACRO 기능을 통합한 하드웨어 Package (하드웨어 표준화로 경제적인 시스템 제공)

• 32 Bits Data bus Architecture and Direct Memory Access

• 향상된 Hardware Position Capture / Multi-Dim. Compare 기능

• 각 채널별 주파수 설정 가능 (PWM, Servo..dead-time)

• 펄스출력 Servo(Stepper) 제어 채널의 엔코더 입력 가능

• Laser 및 방전기 Power 제어를 위한 향상된 Pulse Modulation 기능)

• 16-Bits (x65536) Sinusoidal Encoder Interface (Auto Correction)

• 다양한 Serial Data Encoder interface (SSI, EnDat, Tamakawa, Panasonic, Yaskawa, …)

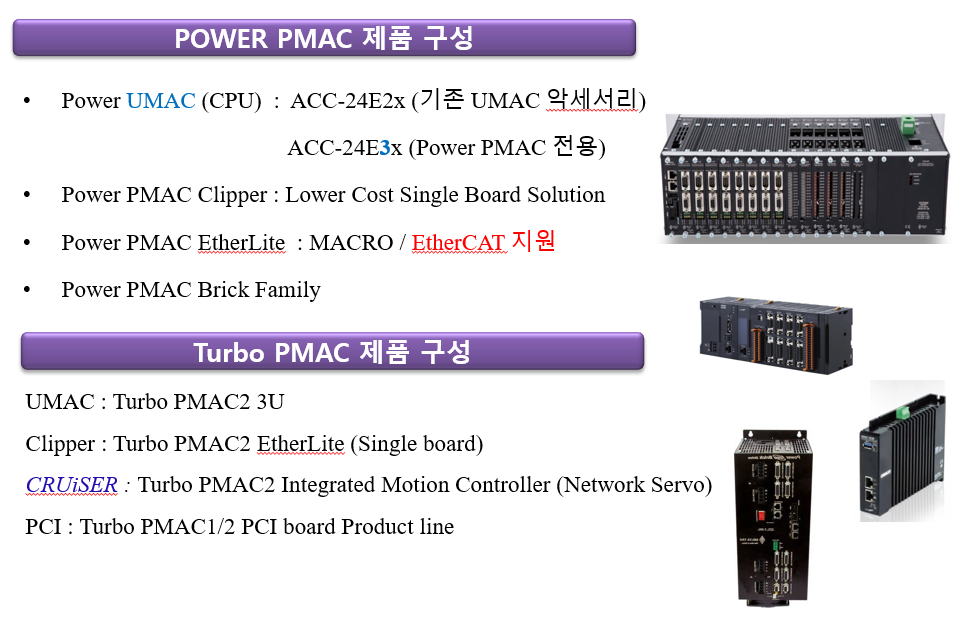

- 제품 구성

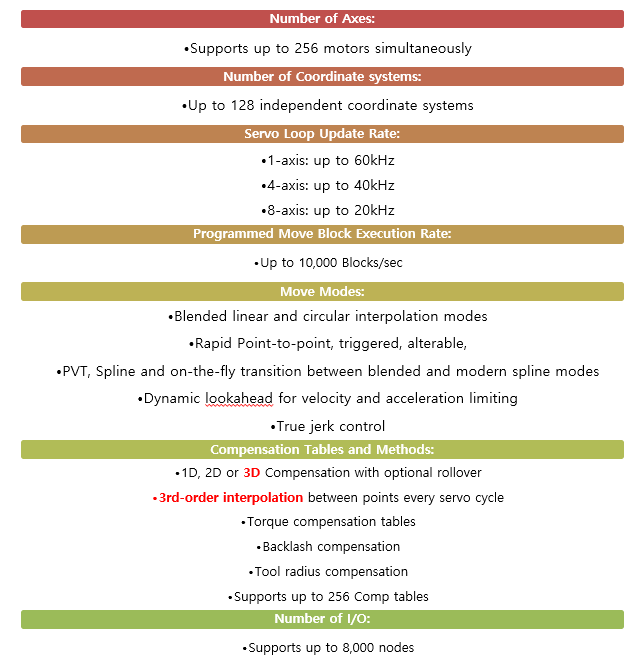

- POWER PMAC Motion Specifications

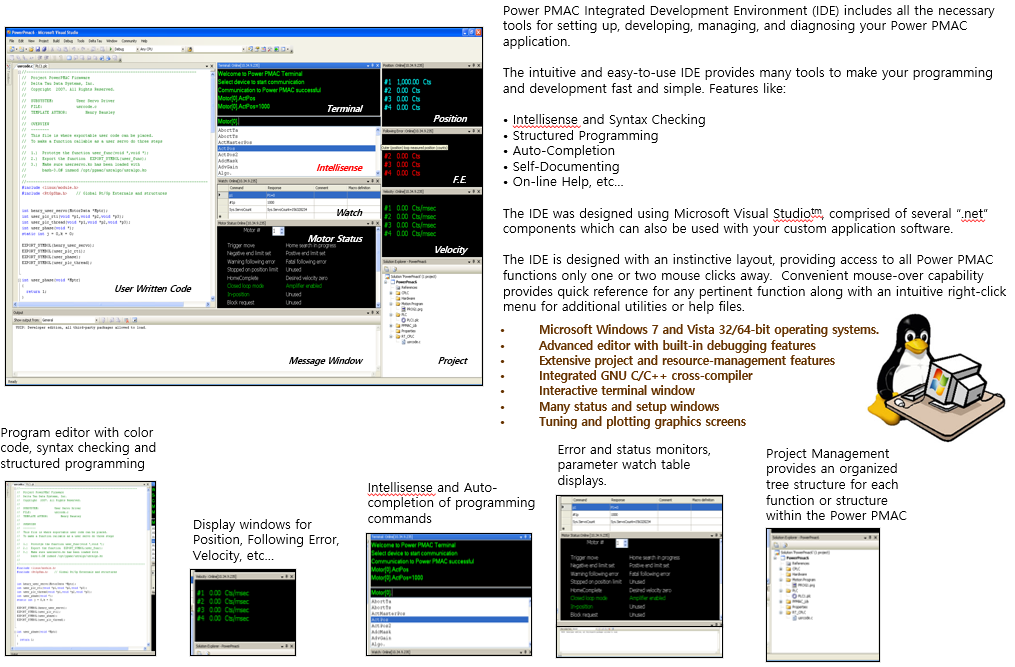

- The Power PMAC IDE Software

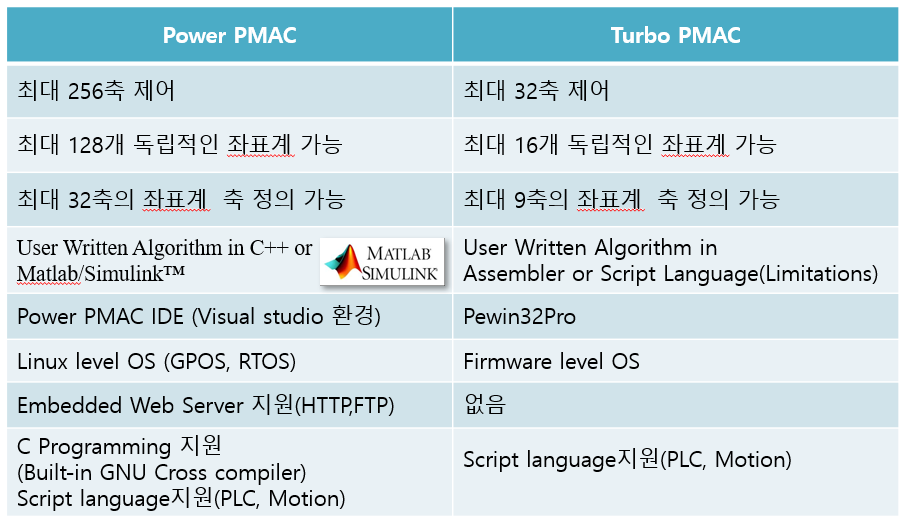

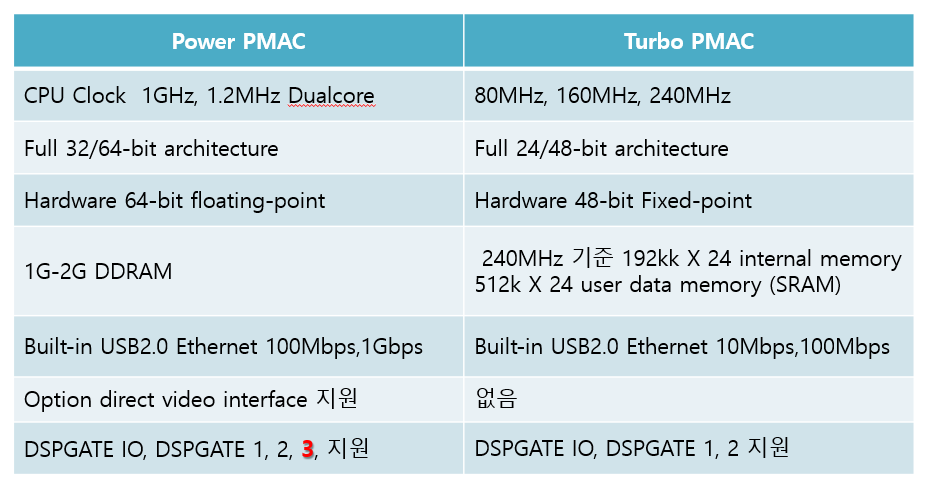

- Power PMAC vs Turbo PMAC (Hardware)

- Power PMAC vs Turbo PMAC (Software)